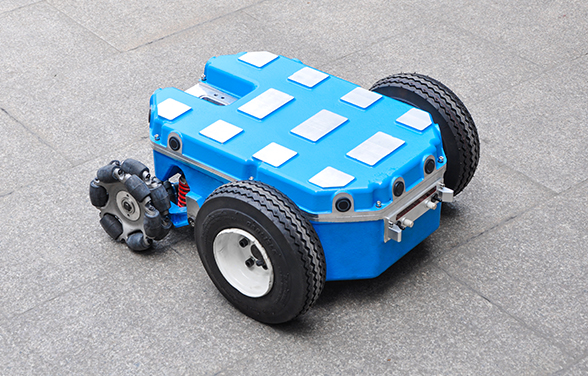

Navigator C1 Two-wheel differential platform

Product Briefing

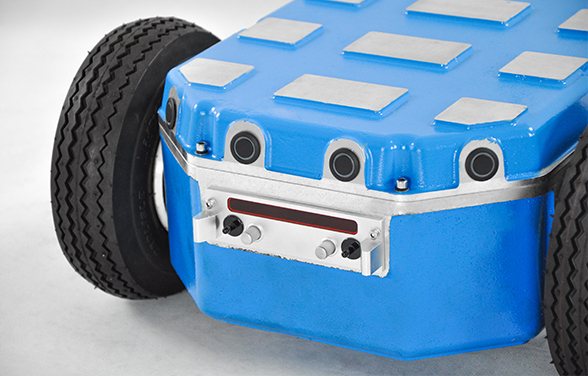

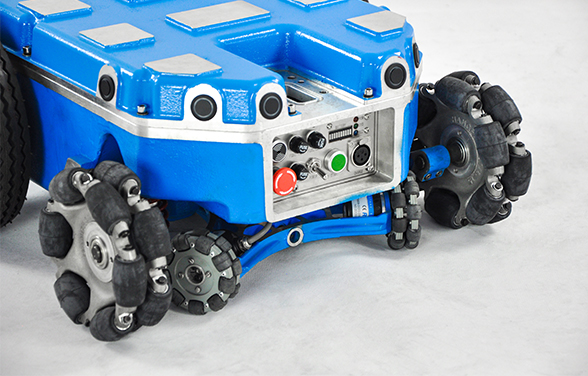

The Navigator series is the representative of high performance and high reliability products. Adopting industrial product design concept, it is designed to provide users with a complete, user-friendly robot system with high performance, high reliability, multiple interface, strict protection grade, long-term continuous work capacity. The Navigator C1 is the robot platform with two inflatable rubber driving wheels and two QLM-15 omni driven wheels equipped with separately hanged hydraulic shock absorbers, which can adapt to all kinds of working environment and complete all kinds of sports efficiently. The chassis of this platform adopts overall casting molding process of aluminum alloy. Navigator C1 uses two high-power coreless motors as the driver, equipped with independent servo driver and the advanced motion controller, which integrates various motion control function, making both CAN bus and RS232 interface available. The development kit provides customers with a complete equipment communication protocol, and also provides examples and demo application source code based on STM32F407, which allows users quickly know how to operate Navigator C1.

Video Display

Product Characteristics

- Omnidirectional driven wheel

- Aluminum alloy integral forming chassis

- Independent suspension of driven wheel hydraulic damping shock absorber

- Industrial grade rubber inflatable tires, omnidirectional wheels

- Hollow cup DC servo motor

- Servo drive

- Multi functional motion controller

- DEMO development board and application code

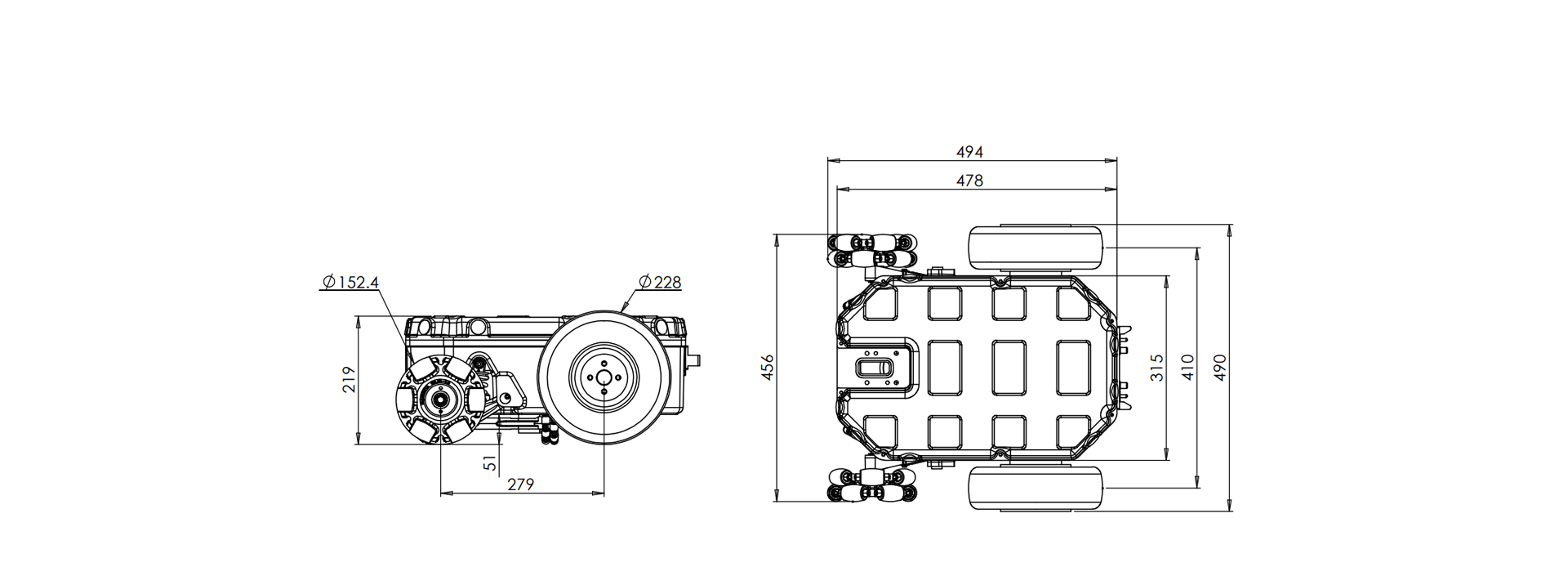

Exterior Dimension

Specification Parameters

| Fuselage Form | Aluminum alloy one-piece molding | Overall Dimension | 494×490×219 |

| Driving Wheel | Rubber Inflatable Wheel | Diameter of Driving Wheel | 228mm |

| Driving Method | Two-wheel independent drive | Suspension Form | Hydraulically damped shock absorber suspension on driven wheel |

| Minimum Ground Clearance | 51mm | Weight | 25kg |

| Rated load Capacity | 50kg | Motor Type | Hollow Cup DC Servo Motor |

| Motor Rated Power | 150W | Motor Encoder | 500 lines/revolution, A and B phase outputs |

| Number of Motors | 2 | Motor Drive | Servo drive, CAN bus, RS232 communication interface |

| Maximum Travel Speed | 1.2m/s | Maximum Rotation Speed | 430°/s |

| Minimum Turning Radius | 0m | Adaptable Terrain | Indoor and outdoor concrete and asphalt pavements with fewer potholes |

| Typical Endurance | Approx. 10h (load 10kg, operating speed 1m/s, operating rate 70%) | Standby Time | >30h |

| On-board Power Output | 5V@5A / 12V@5A / Battery voltage (22.4~29.2V)@>10A | Power Fuse Preset Specification | 5×20/20A |

| Battery | 24V/18.2Ah lithium-ion battery | Battery Quick Change | Support |

| Charger | Input:AC220V~240V / Charging current:5A / Interface:Plug-in type | Accessory | Battery Charger |

| DEMO Board | RHF407 development board (CAN×2, RS232×2, TTL×1, RS485×1, SPI×1, I2C×1, ADC×8, DAC×2, PWM×8, LED×2, keypad×2, independent I/O×24, reusable I/O×29, TF card interface×1, RTC backup battery holder, reusable TFT LCD interface×1) | ||

| Fuselage Form | Aluminum alloy one-piece molding | ||

| Driving Wheel | Rubber Inflatable Wheel | ||

| Driving Method | Two-wheel independent drive | ||

| Minimum Ground Clearance | 51mm | ||

| Rated load Capacity | 50kg | ||

| Motor Rated Power | 150W | ||

| Number of Motors | 2 | ||

| Maximum Travel Speed | 1.2m/s | ||

| Minimum Turning Radius | 0m | ||

| Typical Endurance | Approx. 10h (load 10kg, operating speed 1m/s, operating rate 70%) | ||

| On-board Power Output | 5V@5A / 12V@5A / Battery voltage (22.4~29.2V)@>10A | ||

| Battery | 24V/18.2Ah lithium-ion battery | ||

| Charger | Input:AC220V~240V / Charging current:5A / Interface:Plug-in type | ||

| Overall Dimension | 494×490×219 | ||

| Diameter of Driving Wheel | 228mm | ||

| Suspension Form | Hydraulically damped shock absorber suspension on driven wheel | ||

| Weight | 25kg | ||

| Motor Type | Hollow Cup DC Servo Motor | ||

| Motor Encoder | 500 lines/revolution, A and B phase outputs | ||

| Motor Drive | Servo drive, CAN bus, RS232 communication interface | ||

| Maximum Rotation Speed | 430°/s | ||

| Adaptable Terrain | Indoor and outdoor concrete and asphalt pavements with fewer potholes | ||

| Standby Time | >30h | ||

| Power Fuse Preset Specification | 5×20/20A | ||

| Battery Quick Change | Support | ||

| Accessory | Battery Charger | ||

| DEMO Board | RHF407 development board (CAN×2, RS232×2, TTL×1, RS485×1, SPI×1, I2C×1, ADC×8, DAC×2, PWM×8, LED×2, keypad×2, independent I/O×24, reusable I/O×29, TF card interface×1, RTC backup battery holder, reusable TFT LCD interface×1) | ||

Typical Components

-

QMA-15 omni wheel

-

ULB-16 ultrasonic range-finding sensors

-

MOTC1 motion controller

-

HFmotor-3590 coreless DC servo motor

-

OFPS Incremental positioning device

-

ACDS automatic docking charging device

-

Servo driver

-

RHF407 development board

Typical Research and Application Areas

- Pattern recognition technology research

- Electronic engineering experiment

- Carrying and storage applications

- Route planning technology research

- Mechanical engineering experiment

- Monitoring and investigation application

- Automatic driving technology research

- Embedded system development and experiment

- The robot competition

- Sensor technology research

- Image process technology research

- Mapping application

- Artificial intelligence research

- Multi-robot cooperation technology research

- Flexible manufactur system application

Optional Accessories

- HMC-1 remote control handle

- LPC-16 patrol sensor

- ULB-1 ultrasonic range-finding sensors

- Laser radar

- GPS locator

- Kinect device body sensor