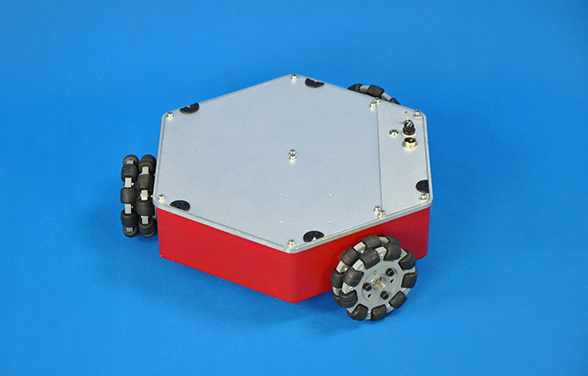

Compass Q1 three-wheeled omni-directional platform

Product Briefing

The Compass series is a small fundamental robot platform. It aims to provide users with a complete mobile robot system with high reliability and multiple interfaces. Compass Q1 is a robot platform with three 90 degrees QL-10 omni wheels. Compared with the traditional gear train, the QL-10 omni wheel is able to accomplish many special movements, like translation, rotation, and simultaneous translation & rotation.The chassis of this platform adopts overall aluminum casting & molding process. Compass Q1 uses three high-power coreless motors as the driver, equipped with multi-axis servo driver, supporting both CAN bus and RS232 interface. The development kit provides customers with a complete equipment communication protocol, and also provides examples and demo application source code based on STM32F407, which allows users quickly know how to operate Compass Q1

Video Display

Product Characteristics

- move to all the directions

- overall aluminum casting & molding process

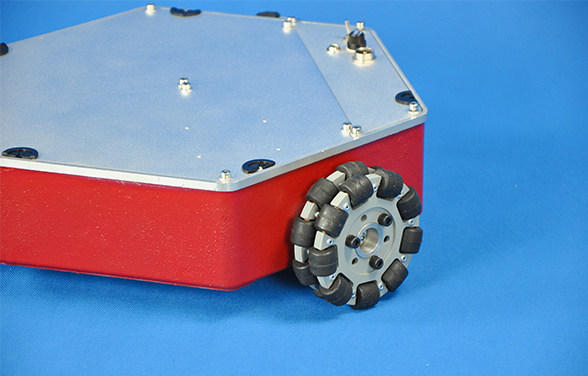

- Industrial grade omnidirectional wheel

- coreless DC servo motor

- servo driver

- demo application source code based on STM32F407

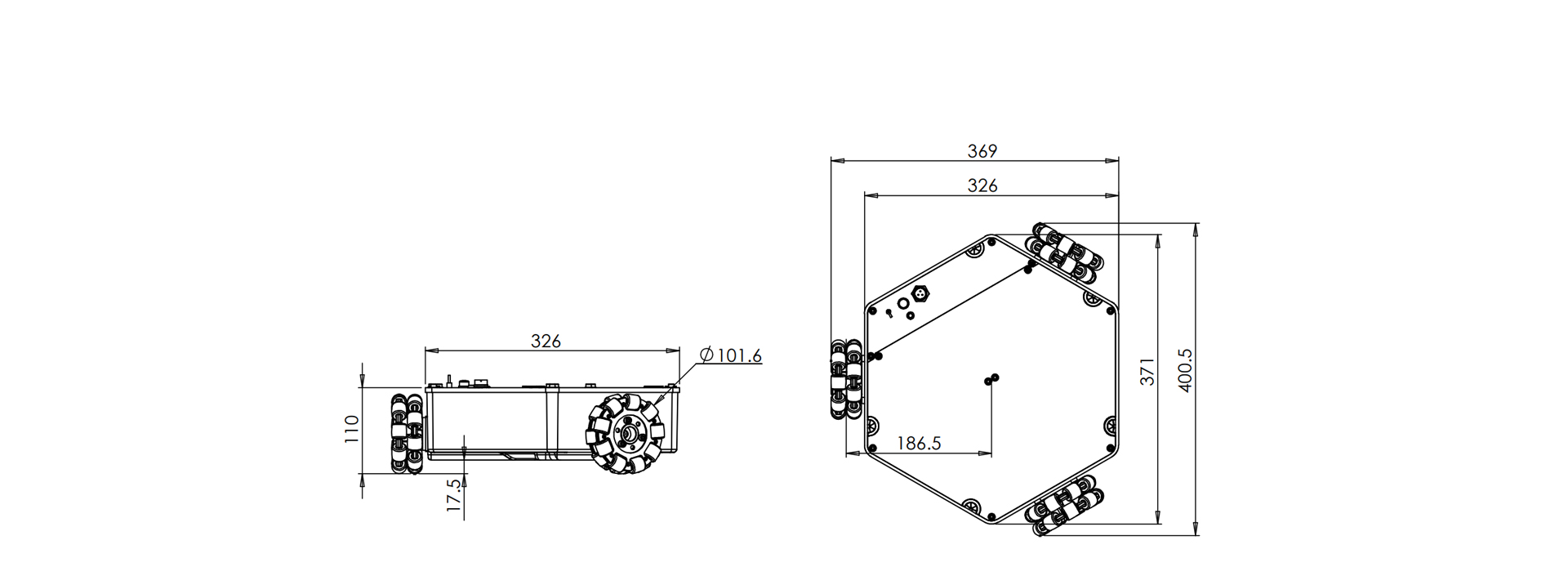

Exterior Dimension

Specification Parameters

| Fuselage Form | Aluminum alloy one-piece molding | Overall Dimension | 369×400.5×110 |

| Driving Wheel | QL-10 Omni-directional Wheel | Diameter of Driving Wheel | 101.6mm |

| Driving Method | Three-wheel independent drive | Suspension Form | No suspension |

| Minimum Ground Clearance | 17.5mm | Weight | 7.1kg |

| Rated load Capacity | 20kg | Motor Type | Hollow Cup DC Servo Motor |

| Motor Rated Power | 30W | Motor Encoder | 500 lines/revolution, A and B phase outputs |

| Number of Motors | 3 | Motor Drive | Servo drive, CAN bus, RS232 communication interface |

| Maximum Travel Speed | 1.2m/s | Maximum Rotation Speed | 365°/s |

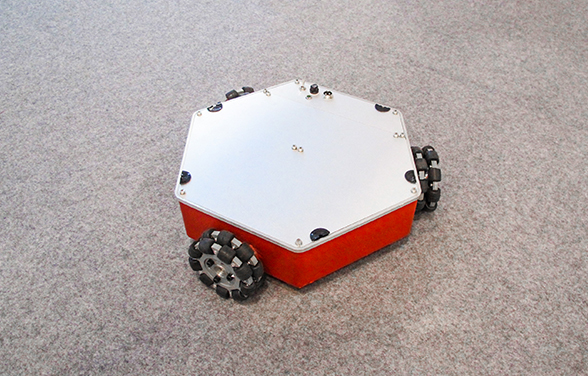

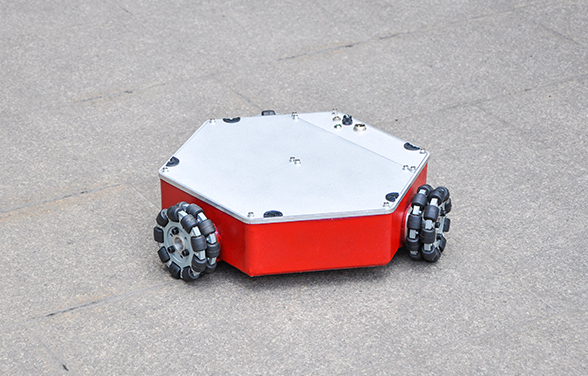

| Minimum Turning Radius | 0m | Adaptable Terrain | Indoor and outdoor concrete and asphalt pavements with fewer potholes |

| Typical Endurance | Approx. 10h (load 10kg, operating speed 1m/s, operating rate 70%) | Standby Time | >30h |

| On-board Power Output | 5V@2.5A / 12V@2.5A / Battery voltage (22.4~29.2V)@>5A | Power Fuse Preset Specification | 5×20/10A |

| Battery | 24V/7.8Ah lithium-ion battery | Battery Quick Change | Support |

| Charger | Input:AC220V~240V / Charging current:3A / Interface:Plug-in type | Accessory | Battery charger, ULB-1 ultrasonic transducer × 5 |

| DEMO Board | RHF407 development board (CAN×2, RS232×2, TTL×1, RS485×1, SPI×1, I2C×1, ADC×8, DAC×2, PWM×8, LED×2, keypad×2, independent I/O×24, reusable I/O×29, TF card interface×1, RTC backup battery holder, reusable TFT LCD interface×1) | ||

| Fuselage Form | Aluminum alloy one-piece molding | ||

| Driving Wheel | QL-10 Omni-directional Wheel | ||

| Driving Method | Three-wheel independent drive | ||

| Minimum Ground Clearance | 17.5mm | ||

| Rated load Capacity | 20kg | ||

| Motor Rated Power | 30W | ||

| Number of Motors | 3 | ||

| Maximum Travel Speed | 1.2m/s | ||

| Minimum Turning Radius | 0m | ||

| Typical Endurance | Approx. 10h (load 10kg, operating speed 1m/s, operating rate 70%) | ||

| On-board Power Output | 5V@2.5A / 12V@2.5A / Battery voltage (22.4~29.2V)@>5A | ||

| Battery | 24V/7.8Ah lithium-ion battery | ||

| Charger | Input:AC220V~240V / Charging current:3A / Interface:Plug-in type | ||

| Overall Dimension | 369×400.5×110 | ||

| Diameter of Driving Wheel | 101.6mm | ||

| Suspension Form | No suspension | ||

| Weight | 7.1kg | ||

| Motor Type | Hollow Cup DC Servo Motor | ||

| Motor Encoder | 500 lines/revolution, A and B phase outputs | ||

| Motor Drive | Servo drive, CAN bus, RS232 communication interface | ||

| Maximum Rotation Speed | 365°/s | ||

| Adaptable Terrain | Indoor and outdoor concrete and asphalt pavements with fewer potholes | ||

| Standby Time | >30h | ||

| Power Fuse Preset Specification | 5×20/10A | ||

| Battery Quick Change | Support | ||

| Accessory | Battery charger, ULB-1 ultrasonic transducer × 5 | ||

| DEMO Board | RHF407 development board (CAN×2, RS232×2, TTL×1, RS485×1, SPI×1, I2C×1, ADC×8, DAC×2, PWM×8, LED×2, keypad×2, independent I/O×24, reusable I/O×29, TF card interface×1, RTC backup battery holder, reusable TFT LCD interface×1) | ||

Typical Components

-

QL-10 omni wheel

-

HFmotor-3230 coreless DC servo motor

-

RHF407 development board

-

ULB-1 ultrasonic range-finding sensors

-

IMDR4 motion controller

Typical Research and Application Areas

- Pattern recognition technology research

- Electronic engineering experiment

- Carrying and storage applications

- Route planning technology research

- Mechanical engineering experiment

- Monitoring and investigation application

- Automatic driving technology research

- Embedded system development and experiment

- The robot competition

- Sensor technology research

- Image process technology research

- Mapping application

- Artificial intelligence research

- Multi-robot cooperation technology research

- Flexible manufactur system application

Optional Accessories

- HMC-1 remote control handle

- LPC-16 patrol sensor

- ULB-1 ultrasonic range-finding sensors

- Laser radar

- GPS locator

- Kinect device body sensor